Geotechnical Boring

Geotechnical investigations are performed to learn about the physical properties of the rocks and soil near locations that are being considered for construction in a variety of situations. Before any ground level or underground work can be done, it’s necessary that those involved in completing the project know what ground conditions they are working with and what they may encounter as they progress. This information is important to ensure that they are using the correct tools for the job and that they will not encounter any unexpected obstacles.

Geotechnical Boring Program

For the SCMAGLEV project, approximately 75% of the two proposed route alternatives from Washington DC to Baltimore will be in deep underground tunnels. As such the independent environmental impact statement process (EIS), as well as BWRR’s engineers require a detailed study of the area’s geology. The initial step of this study is done through a process of taking borings at identified locations along the 40-mile route. Study of the deep underground geology will reveal pertinent soil characteristics and underground conditions which will help establish the parameters for deep tunneling.

Review of Previous Geotechnical Studies

The geotechnical boring analysis begins with study of historical geologic documents – studying existing geologic maps of the area as well as previous reports/investigations done in the area. Historical study is done to develop a conceptual geologic cross section and identify any potential technical restraints/issues for the project. There are a large number of tunnels and other infrastructural elements under our feet already (think subway, power, telecommunications, water, gas, sewer, and stormwater systems). The early historical study creates a general geologic survey that is used to determine which areas may need further investigation. It also determines the number of boreholes needed, the type of drills, and the type of samples needed. For example, tunneling in shallow soil requires more borings to establish geographic features, whereas tunneling in deep rock may require fewer borings, as rock formations tend to have more consistency over larger distances. In the case of the Maryland SCMAGLEV EIS study, it was established that a series of 24 boreholes was needed along the potential routes.

The Geotechnical Boring Process

Beginning in March 2018, areas along the potential routes were surveyed. Utility marking crews identified appropriate locations along the routes for borehole sampling. In most cases, the boring sites were placed in vacant lots or public lands, and away from private land and residences. At the established survey locations, study crews removed ground cover and other obstacles and establish a safe working distance around the drilling equipment. The actual boring process made use of truck or tractor-based drill platforms. The drill platforms used a diesel engine to rotate an approximately 4-inch-wide metal drill bit into the ground. The drill bit was attached to a hollow metal shaft that collected a cylindrical sample of soil and rock as it moved down. As the drill was forced deeper into the ground, additional shafts were added to retrieve deeper and deeper core samples. As the samples were removed from the ground they were labeled, documented, and packaged for transport to a laboratory for study. After the two- to five-day operation, crews backfilled the boreholes and restored the locations to their previous condition.

Beginning in March 2018, areas along the potential routes were surveyed. Utility marking crews identified appropriate locations along the routes for borehole sampling. In most cases, the boring sites were placed in vacant lots or public lands, and away from private land and residences. At the established survey locations, study crews removed ground cover and other obstacles and establish a safe working distance around the drilling equipment. The actual boring process made use of truck or tractor-based drill platforms. The drill platforms used a diesel engine to rotate an approximately 4-inch-wide metal drill bit into the ground. The drill bit was attached to a hollow metal shaft that collected a cylindrical sample of soil and rock as it moved down. As the drill was forced deeper into the ground, additional shafts were added to retrieve deeper and deeper core samples. As the samples were removed from the ground they were labeled, documented, and packaged for transport to a laboratory for study. After the two- to five-day operation, crews backfilled the boreholes and restored the locations to their previous condition.

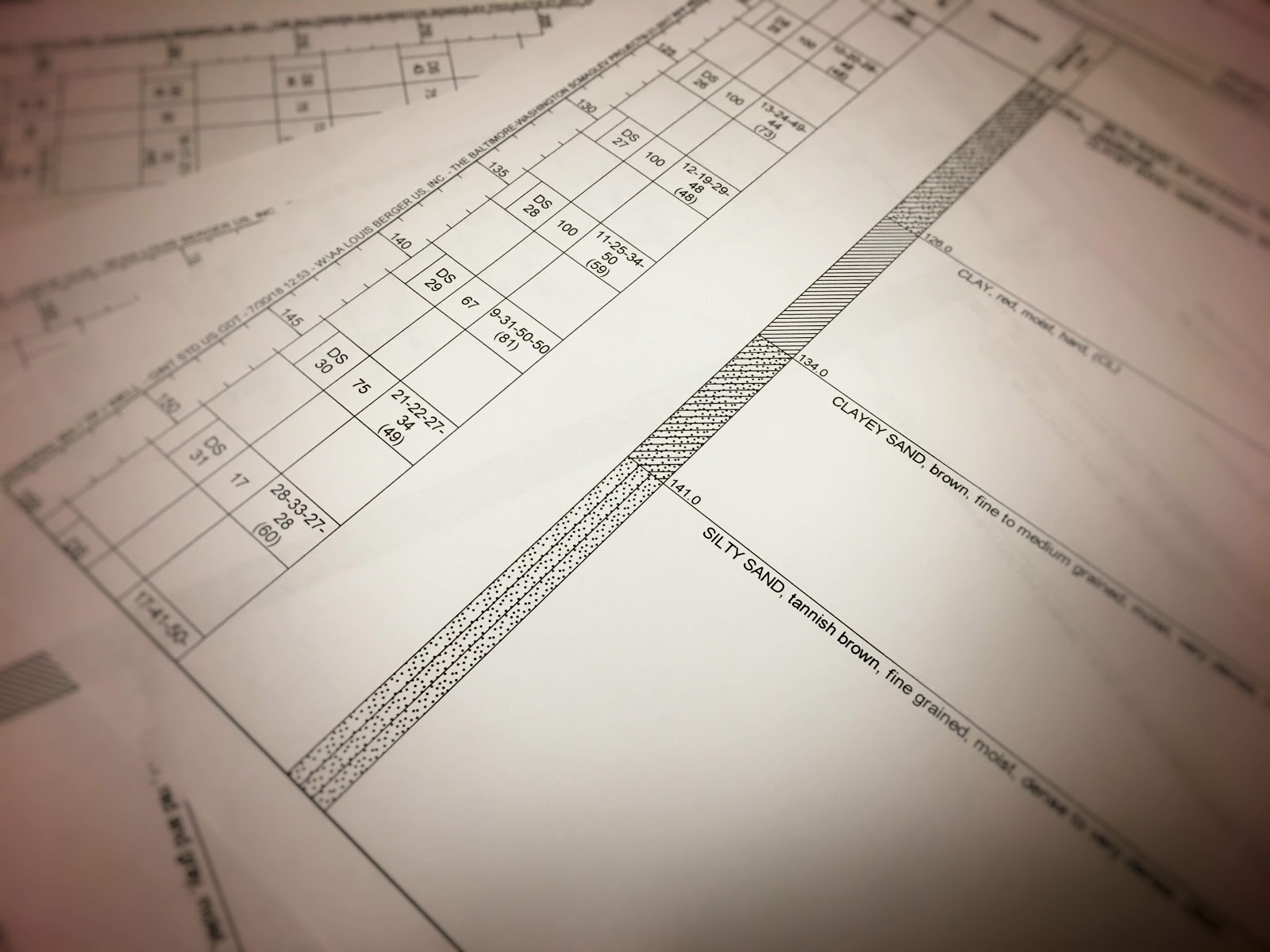

In the laboratory, the samples are then tested and classified for things like soil type, clay levels, rock type and quality, moisture levels, and density. This data is then matched with data from the previous historical studies and used to generate a detailed geologic map and database of the area along the routes. The geologic survey will establish the relative location of soil, rock formations, and ground water levels along the route.

As part of the EIS process, geotechnical results are used to determine project feasibility, environmental impacts, type of tunnel boring equipment and procedures needed, cost estimates, timelines, groundwater mitigation procedures, and other engineering details.

For more information or for help with questions about the Environmental Impact Statement process please visit the project website. For more information about the SCMAGLEV and the technology behind the World’s Fastest Train, please contact us here. To stay up to date and help us spread the word, please join our mailing list and join us online @NortheastMaglev.

References:

Raines, Greg. September 12, 2016. Geotechnical Site Investigations for Tunneling. Breakthroughs in Tunneling. Retrieved from https://tunnelingshortcourse.com/2016-presentations/raines-geotechnical-site-investigations.pdf